Smart design, precision engineering

Our Unique System

The TRAKRAP System is a unique combination of the TRAKRAP machine, coupled with specially design ultra thin stretch film and innovative pack designs that come together to provide the most cost effective, environmentally friendly solution available. TRAKRAP machines are the result of 15 years of design and development. They are built by our skilled engineers, in our state-of-the-art engineering facility in Skelmersdale, Lancashire. We operate a lean production flow to make sure that each machine is built in the most efficient way.

DOES YOUR COMPANY

- Need to meet the demands of supermarkets for transit or retail ready packaging? TRAKRAP delivers.

- Need to save packaging materials, energy and money? TRAKRAP delivers.

- Need to prepare packaging for shelf more quickly? TRAKRAP delivers.

- Need fantastic product presentation on shelf? TRAKRAP delivers.

- Need a bespoke secondary packaging solution – self-supporting, ambient, frozen? TRAKRAP delivers.

- Need to meet EEC environmental directives for recycling and energy efficiency? TRAKRAP delivers.

- Need a solution with no Cap-Ex and controllable costs? – TRAKRAP delivers.

Technology

At TRAKRAP the pace of innovation is relentless in our quest to always deliver the lowest cost, most environmentally friendly pack. Our continual investment in the Trakrap machine, and cold film technology, means we are uniquely placed to meet this goal because we can develop solutions that no one else can. For this reason we embrace a much wider view of technology that includes not only the unique TRAKRAP machine, but pack design, film development and knowledgeable people who can make change happen. We call this the "TRAKRAP System"

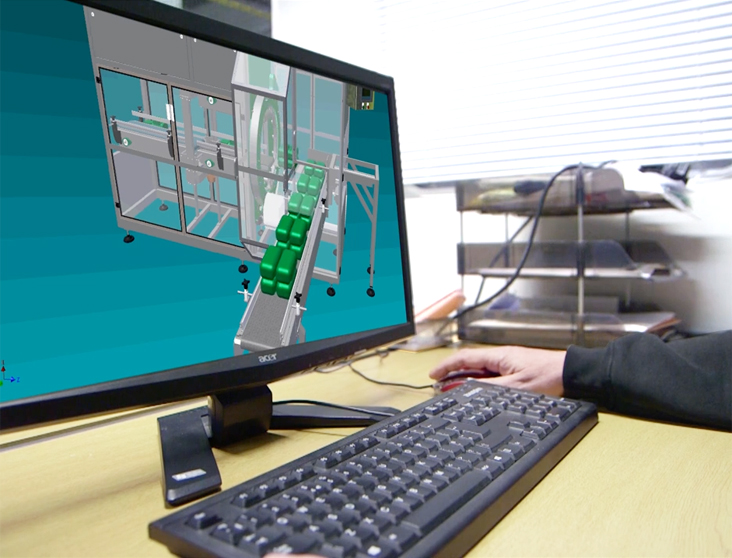

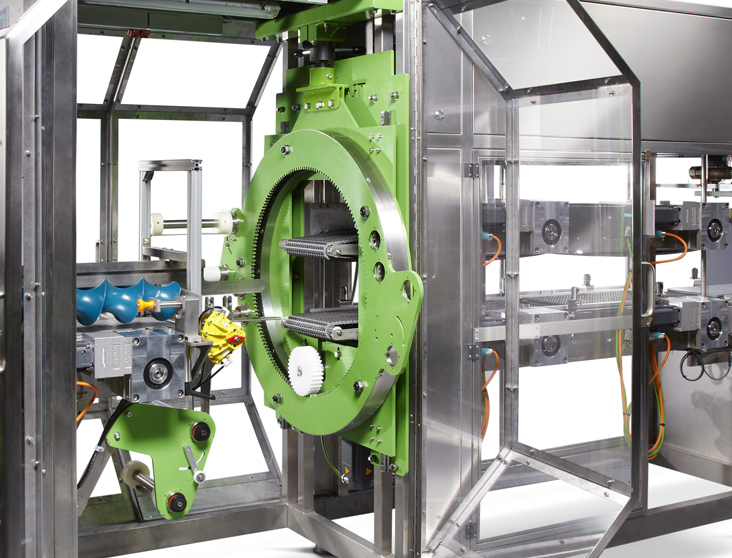

Machine

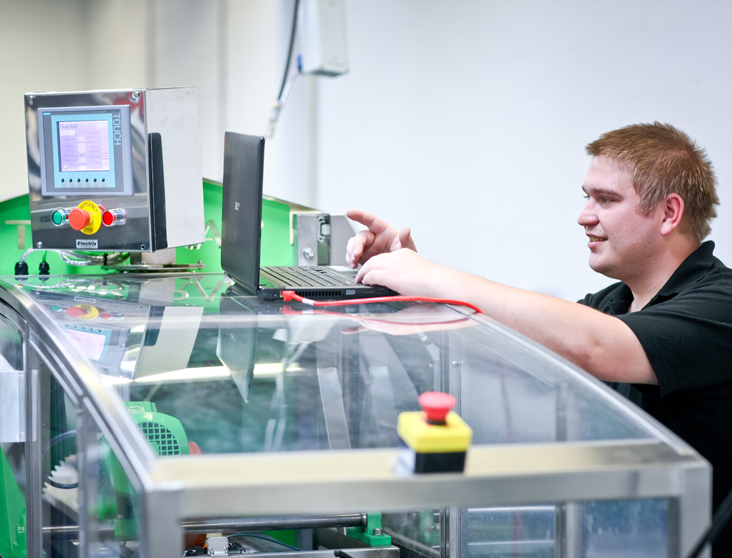

At the heart of the TRAKRAP System is the TRAKRAP machine. Since we obtained our very first patent, we have continued to invest heavily in machine technology in order to increase the variety of packs we can offer, increase production speeds, reduce changeover times, deliver class leading reliability and first and foremost, do everything safely. But it doesn't stop there, the ergonomics of how the machine is operated and controlled, even how it is cleaned simply and quickly, are all areas where we engage industry leading technology.

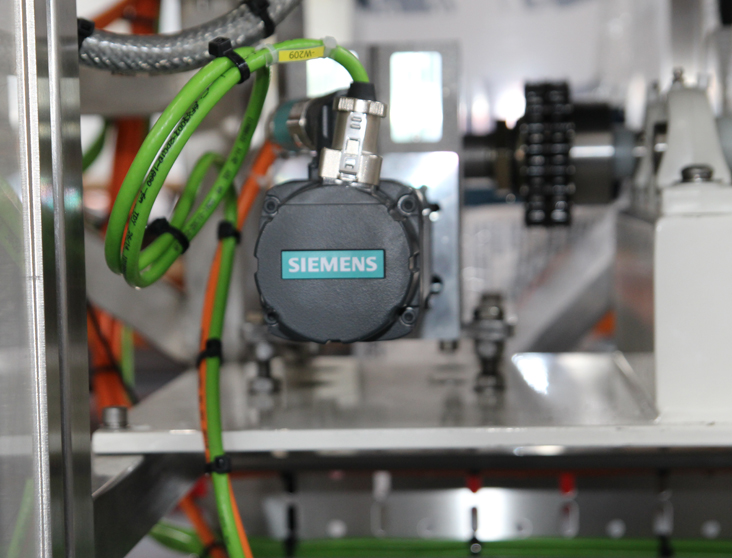

At the heart of all this is our investment in the very latest Siemens systems. Dynamic positioning and precise motion control through Simotion, allows cycle rates to be increase without losing accuracy and allows us to accurately meter film. All this is controlled by the outstanding Simanic S7 processor, operated through HMI or MES interfaces and guarded by Sirius safety systems, all programmed in one environment via TIA portal. No matter where in the world your machine is installed, Siemens support will be on hand.

The modular design of the system allows for different infeeds, cutting mechanisms and outfeeds all centred around the same film tensioning and wrapping system. When you couple this with a variety of different cutting/crimping solutions, film snap detection and local (HMI) or remote (MES) control you can see we have machines operating that are managing over 25 different pack types. So whether you have uncollated packs, trays, tins, boxes, tubs, cartons, bags or whatever, TRAKRAP have the technology.

This wholly, British designed, developed and made, machine is designed to operate within restricted footprints. Furthermore, it can easily be integrated within existing lines and, working with specialist partners, we can offer complete end-of-line solutions.

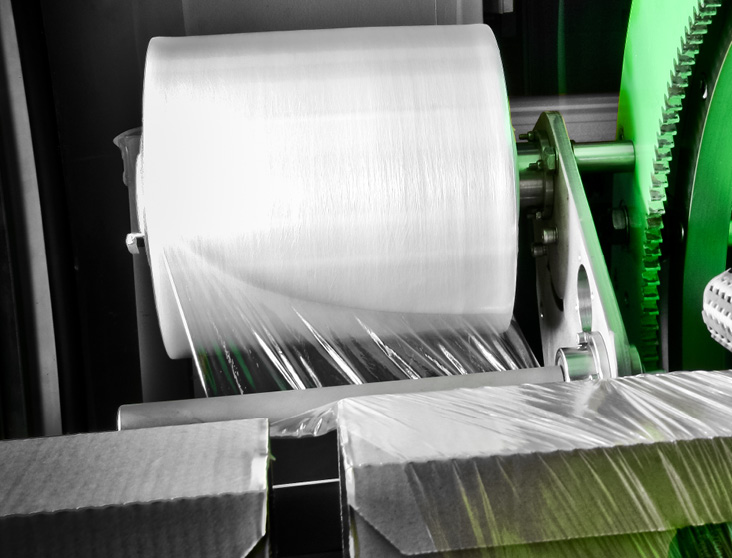

Film

Finding a film that has exact stretch characteristics, strength and "stickiness" is difficult enough, but when you overlay an additional requirement for these properties to vary to different degrees, in different directions and be only 7 microns thick it's a technological challenge. Working closely with our suppliers we have developed one film, in one size that wraps the vast majority of our packs, significantly reducing the complexity and cost of managing and stocking multiple film sizes for different pack sizes. Furthermore there's 5.7km of film on a reel, which goes a long way, requiring less changeovers.

Our film works on a huge variety of products from heavy weight tins to fresh chilled or ambient foodstuff, it is made from top quality substrate that is Food Contact Approved making it compliant with European Regulations no.s 10/2011 & 1935/2004.

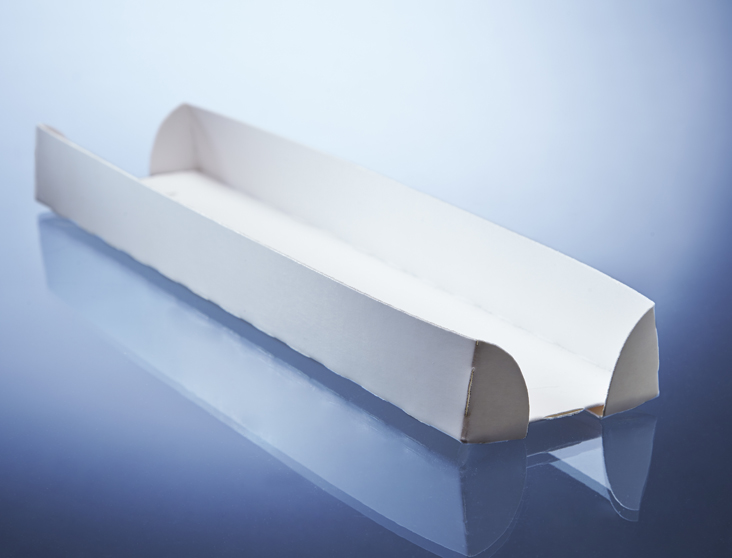

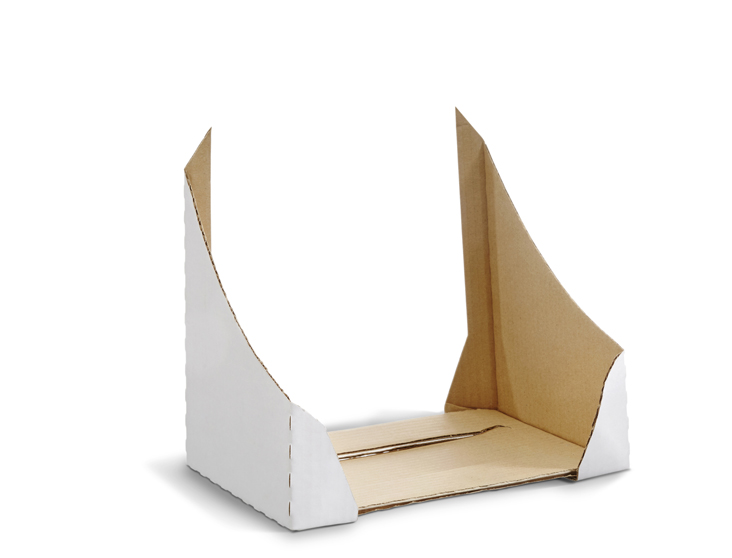

Pack Design

TRAKRAP are independent, so we can develop the latest solutions that deliver what our customers want. Whether it's increasing sales through better "on shelf" presentation, or taking the time out of shelf replenishment through packs that are quicker to prepare for shelf, quicker to break down and quicker to dispose of, or even taking cost out of the supply chain through less inbound pallets or packs that are quicker to fill. All use less material, so whether it's corrugate, cartonboard or RPET, using our approved suppliers, we can get the right solution to you. The technology we have in pack design is truly ground breaking.

TRAKRAP are proud to have been shortlisted for an impressive three awards in this year's UK Packaging Awards FIND OUT MORE

People & Knowledge

We recognise that the latest technology means change is inevitable if it is to be implemented. Our technology doesn't just extend to machines, or films, or packs, but we have the very latest change management programmes led by our people who have a proven track record in making it work. We work with all our customers to ensure that change is fast, seamless and, above all, successful.

No Capital Expenditure

The only thing that's certain, in the fast moving world of FMCG, is that change is inevitable! One of the downsides for manufacturers is that this raises the stakes when buying capital equipment and often leads to a long, drawn out decision making process that leaves the potential for cost savings "on the table" instead of on the bottom line.

At TRAKRAP, we are confident that our system will deliver a lower cost, more environmentally friendly solution and we want our customers to reep these benefits as soon as possible. We have done this by providing our system on a cost per case basis without any requirement for Capex. Our thinking is simple, if each pack costs less to pack and there is no capital cost, why can't you just get on with it?

Typically, contracts last for 5 years, but this is a long time in retailing, so we have introduced a no questions "walk away" clause after 2.5 years. We have done this because we are confident that the system will enable you to unlock very significant savings in your business not only in secondary packaging material costs, but also in areas such as pallet handling and storage, line speeds and changeover times. In short, we expect you will want the system for a very long time!

In case you're wondering how we can do this, it's not magic! Our machine is powered by the very latest Siemens control systems and we, in turn, are powered by Siemens Financial Services (SFS) as our funding partner. All this is factored in to your cost per case.

So, if you're looking for a secondary packaging system that has a lower cost per pack, the opportunity for wider efficiency savings, is quick and easy to install and requires no capital expenditure, we have the solution for you.